MAGNETIC PARTICLE TESTING (MPT)

Magnetic particle inspection is a non-destructive testing process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron , nickel , cobalt and some of their alloys with the help of applying different types of currents.

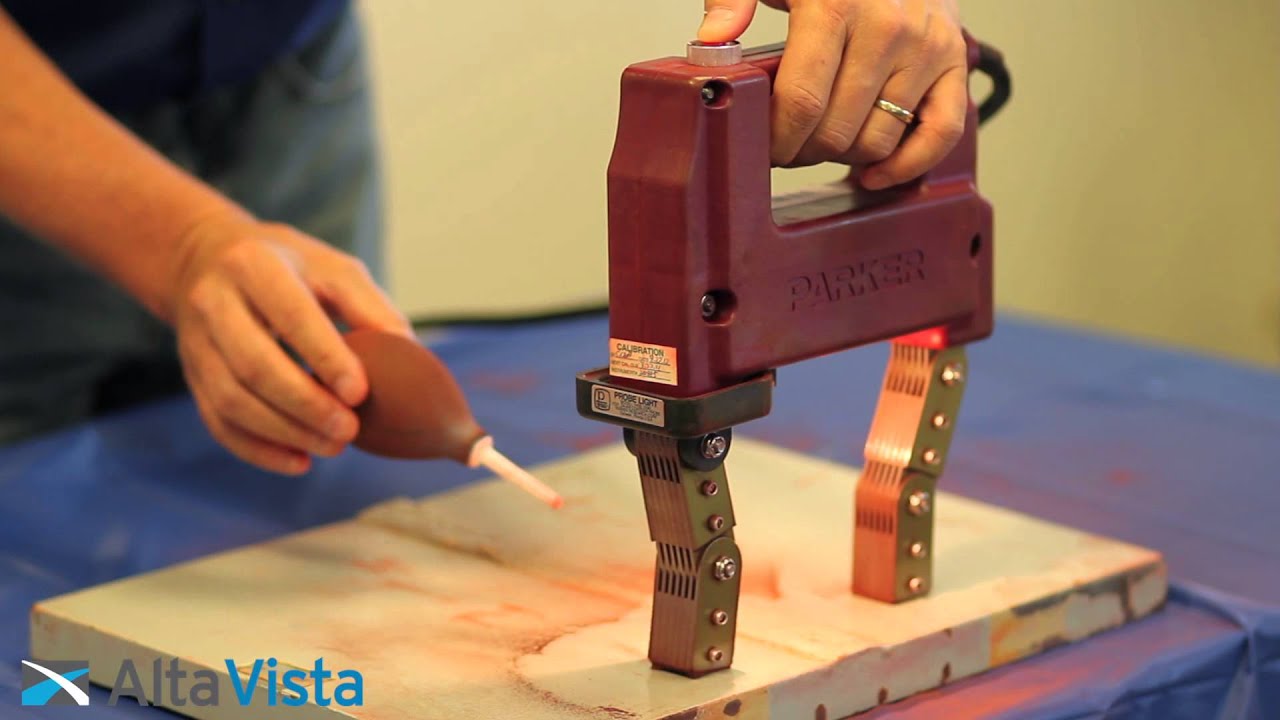

We provide four types of magnetic particle testing

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

- Headshot

- Yoke

- Coil shot

- Prod

There are several benefits of MPT as it is highly portable generally inexpensive and does not need a straight per- cleaning operation MPT is also one of the best option for detecting fine shallow surface cracks It is fast, easy and will work through thin coating.

When the workpiece to be inspected is magnetized magnetic flux is induced, If there is a flaw on the surface magnetic flux leaks into the air at the position of flaw, then magnetic particles are applied to surface, these magnetic particles will migrate to the flaw where the magnetic flux leaks and forms a flaw indication that is several ten times of actual flaw width, the inspector visually indentifies the flaw.